Ana ewonan plastik ing pasar kanggo prototipe cepet utawa produksi skala cilik - milih plastik sing tepat kanggo proyek tartamtu bisa dadi akeh banget, utamane kanggo para penemu utawa pengusaha sing kepengin banget. Saben materi nggambarake kompromi babagan biaya, kekuatan, keluwesan lan permukaan. Sampeyan kudu nimbang ora mung aplikasi bagean utawa produk, nanging uga lingkungan sing bakal digunakake.

Umumé, plastik rekayasa wis ningkatake sifat mekanik sing nyedhiyakake daya tahan sing luwih gedhe lan ora owah sajrone proses manufaktur. Sawetara jinis plastik uga bisa diowahi kanggo nambah kekuatan, uga impact lan tahan panas. Ayo nyilem menyang macem-macem bahan plastik kanggo nimbang gumantung saka fungsi bagean pungkasan utawa produk.

Salah sawijining resin sing paling umum digunakake kanggo nggawe bagean mekanik yaiku nilon, uga dikenal minangka poliamida (PA). Nalika poliamida dicampur karo molybdenum, nduweni permukaan sing alus kanggo gerakan sing gampang. Nanging, gear nilon-on-nilon ora dianjurake amarga, kaya plastik, padha cenderung tetep bebarengan. PA wis nyandhang dhuwur lan resistance abrasion, lan mechanical apik ing suhu dhuwur. Nylon minangka bahan sing cocog kanggo nyetak 3D kanthi plastik, nanging nyerep banyu saka wektu.

Polyoxymethylene (POM) uga pilihan banget kanggo bagean mechanical. POM minangka resin asetal sing digunakake kanggo nggawe DuPont's Delrin, plastik terkenal sing digunakake ing gear, sekrup, roda lan liya-liyane. POM nduweni kekuatan lentur lan tensile dhuwur, kaku lan atose. Nanging, POM rusak dening alkali, klorin lan banyu panas, lan angel kanggo tetep bebarengan.

Yen proyek sampeyan minangka wadhah, polipropilena (PP) minangka pilihan sing paling apik. Polipropilena digunakake ing wadhah panyimpenan pangan amarga tahan panas, ora kena lenga lan pelarut, lan ora ngeculake bahan kimia, dadi aman kanggo dipangan. Polipropilena uga nduweni keseimbangan kaku lan kekuatan impact sing apik, saengga gampang nggawe puteran sing bisa ditekuk bola-bali tanpa rusak. Uga bisa digunakake ing pipa lan selang.

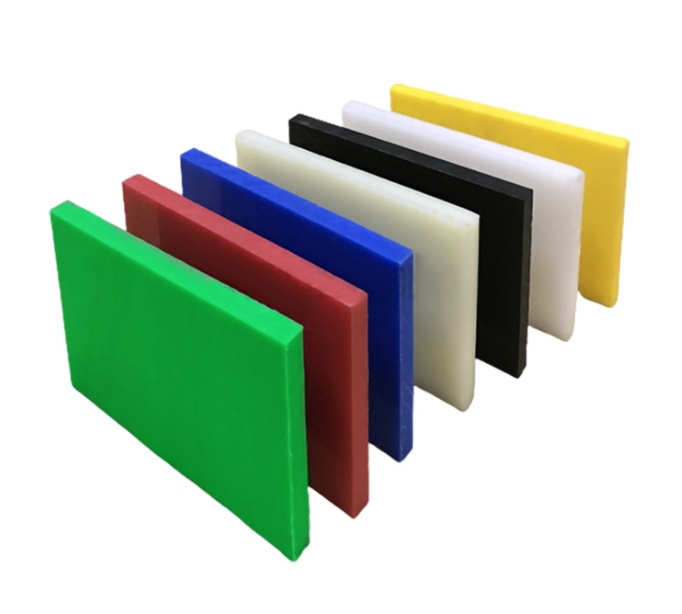

Pilihan liyane yaiku polyethylene (PE). PE minangka plastik paling umum ing donya kanthi kekuwatan, kekerasan lan kaku sing sithik. Biasane plastik putih susu sing digunakake kanggo nggawe botol obat, susu lan wadhah deterjen. Polyethylene tahan banget kanggo macem-macem bahan kimia nanging nduweni titik leleh sing sithik.

Bahan Acrylonitrile butadiene styrene (ABS) becik kanggo proyek apa wae sing mbutuhake resistensi impact dhuwur lan tahan luh lan fraktur sing dhuwur. ABS entheng lan bisa dikuwatake nganggo fiberglass. Luwih larang tinimbang styrene, nanging tahan suwe amarga kekerasan lan kekuwatane. Pemodelan 3D ABS fusion-nyetak kanggo prototyping kanthi cepet.

Amarga sifate, ABS minangka pilihan sing apik kanggo piranti sing bisa dipakai. Ing Star Rapid, kita nggawe kasus jam tangan pinter kanggo E3design nggunakake plastik ABS/PC sing wis dicithak ireng sing wis dicet ireng. Pilihan saka materi iki ndadekake kabeh piranti relatif entheng, lan uga nyedhiyakake kasus sing bisa nahan guncangan sok-sok, kayata nalika jam tangan kena permukaan sing atos. Polystyrene impact dhuwur (HIPS) minangka pilihan sing apik yen sampeyan butuh bahan sing serbaguna lan tahan benturan. Materi iki cocok kanggo nggawe kasus alat daya tahan lama lan kasus alat. Sanajan HIPS terjangkau, nanging ora dianggep ramah lingkungan.

Akeh proyek njaluk resin cetakan injeksi kanthi elastisitas kaya karet. Thermoplastic polyurethane (TPU) minangka pilihan sing apik amarga akeh formulasi khusus kanggo elastisitas dhuwur, kinerja suhu rendah lan daya tahan. TPU uga digunakake ing piranti daya, roller, insulasi kabel, lan barang olahraga. Amarga resistensi pelarut, TPU nduweni kekuatan abrasi lan geser sing dhuwur lan bisa digunakake ing akeh lingkungan industri. Nanging, dikenal kanggo nyerep kelembapan saka atmosfer, dadi angel diproses sajrone produksi. Kanggo cetakan injeksi, ana karet termoplastik (TPR), sing murah lan gampang ditangani, kayata kanggo nggawe grip karet sing nyerep kejut.

Yen bagean sampeyan mbutuhake lensa utawa jendhela sing cetha, akrilik (PMMA) paling apik. Amarga saka rigidity lan resistance abrasion, materi iki digunakake kanggo nggawe jendhela pecah kayata plexiglass. PMMA uga polesan kanthi apik, nduweni kekuatan tarik sing apik, lan biaya efektif kanggo produksi volume dhuwur. Nanging, iku ora minangka impact utawa tahan kimia minangka polycarbonate (PC).

Yen proyek sampeyan mbutuhake materi sing luwih kuwat, PC luwih kuwat tinimbang PMMA lan nduweni sifat optik sing apik, dadi pilihan sing cocok kanggo lensa lan jendhela anti peluru. PC uga bisa ditekuk lan dibentuk ing suhu kamar tanpa rusak. Iki migunani kanggo nggawe prototipe amarga ora mbutuhake alat cetakan sing larang. PC luwih larang tinimbang akrilik, lan paparan banyu panas sing suwe bisa ngeculake bahan kimia sing mbebayani, saengga ora cocog karo standar keamanan pangan. Amarga impact lan resistance goresan, PC becik kanggo macem-macem aplikasi. Ing Star Rapid, kita nggunakake materi iki kanggo nggawe omah kanggo terminal genggam Muller Commercial Solutions. Part iki CNC machined saka pamblokiran ngalangi saka PC; awit iku kudu rampung transparent, iki sanded dening tangan lan uap polesan.

Iki mung ringkesan ringkes babagan sawetara plastik sing paling umum digunakake ing manufaktur. Umume iki bisa diowahi nganggo serat kaca sing beda, penstabil UV, pelumas utawa resin liyane kanggo entuk spesifikasi tartamtu.

Gordon Stiles minangka pangadeg lan presiden Star Rapid, prototyping kanthi cepet, alat cepet lan perusahaan manufaktur volume sithik. Adhedhasar latar mburi teknik, Stiles ngedegake Star Rapid ing taun 2005 lan ing pimpinane, perusahaan kasebut wis dadi 250 karyawan. Star Rapid nggarap tim insinyur lan teknisi internasional sing nggabungake teknologi canggih kayata printing 3D lan mesin multi-axis CNC kanthi teknik manufaktur tradisional lan standar kualitas dhuwur. Sadurunge gabung karo Star Rapid, Styles duwe lan ngoperasikake STYLES RPD, perusahaan prototipe lan perkakas paling gedhe ing Inggris, sing didol menyang ARRK Eropa ing taun 2000.

Wektu kirim: Apr-19-2023