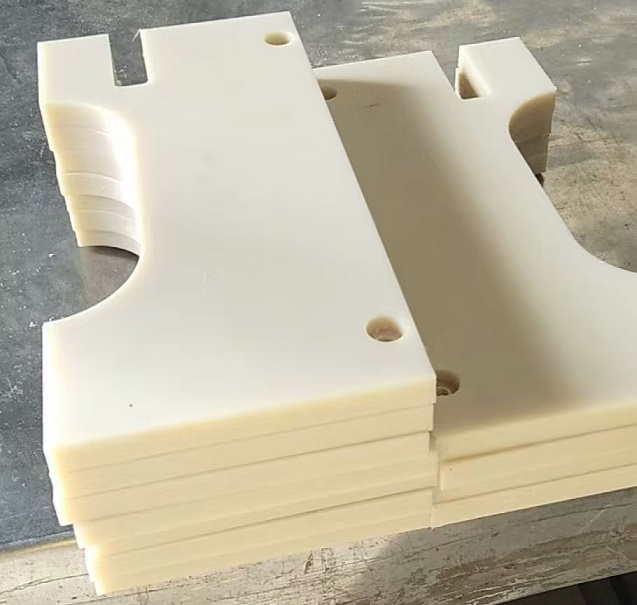

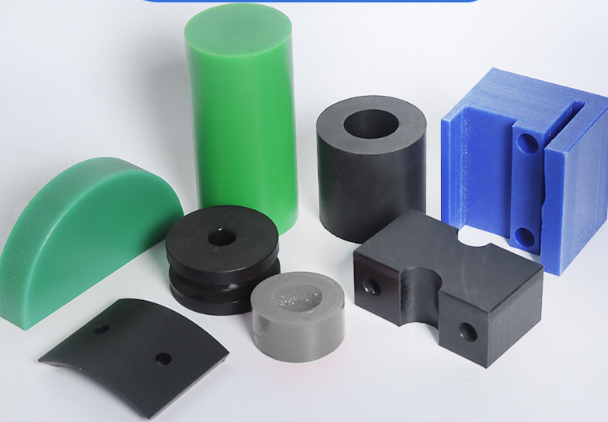

The cast MC nylon is available in various sizes and shapes, making it versatile for different engineering needs. Its machinability allows for easy fabrication and customization, making it a popular choice for manufacturers looking for a cost-effective and durable material for their products. The material can be easily machined, drilled, and tapped to meet specific design requirements, offering flexibility in production processes.

New advances in abrasive technology allow machining center operators to perform surface finishing and other machining operations simultaneously, thereby reducing cycle times, improving quality, and saving time and money on offline finishing. Abrasive finishing tools can be easily integrated into CNC machine rotary tables or tool holding systems.

While contract machine shops are increasingly turning to these tools, others are wary of using abrasives in expensive CNC machining centers. This concern often stems from the common belief that “abrasives” (like sandpaper) leave behind a lot of grit and debris that can clog cooling lines or damage exposed slideways or bearings. These fears are largely unfounded.

It is a misconception that “abrasives” are the same thing. However, a distinction must be made between abrasives used for aggressive material removal and abrasive finishing tools. Finishing tools produce virtually no abrasive particles during use, and the amount of abrasive particles produced is comparable to the metal chips, grinding dust, and tool wear generated during the machining process.

Removing burrs and sharp edges from cross-drilled holes and other hard-to-reach areas such as undercuts, slots, crevices, or internal bores is essential. Failure to remove burrs can result in plugging or turbulence in the flow of fluids, lubricants, and gases through critical passages.

The workpiece is clamped in a chuck, mounted on a faceplate, or clamped between centers and rotated while a cutting tool (usually a single-point tool) is fed into the workpiece along its periphery or along its end face or surface. These processes include straight turning (cutting along the periphery of a workpiece); cone turning (forming a cone); step turning (turning parts of different diameters on the same workpiece); chamfering (chamfering an edge or shoulder); facing (trimming the end); threading (usually external, but may be internal); roughing (extensive metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chuck lathes, automatic lathes, and similar machines.

Post time: Mar-17-2025