Kukho amawaka eeplastiki kwiimarike zeprototyping ekhawulezayo okanye imveliso encinci - ukukhetha iplastiki efanelekileyo kwiprojekthi ethile kunokuba yinto enzima, ngakumbi kubavelisi abanomdla okanye abashishini abanomdla. Isixhobo ngasinye simele ukulungelelana ngokweendleko, amandla, ukuguquguquka kunye nokugqitywa komphezulu. Kuyimfuneko ukuqwalasela kuphela ukusetyenziswa kwenxalenye okanye imveliso, kodwa kunye nendawo eya kusetyenziswa kuyo.

Ngokubanzi, iiplastiki zobunjineli ziye zaphucula iipropathi zomatshini ezinika ukuqina okukhulu kwaye azitshintshi ngexesha lenkqubo yokuvelisa. Ezinye iintlobo zeplastiki nazo zinokuguqulwa ukuze ziphucule amandla azo, kunye nefuthe kunye nokumelana nobushushu. Masingene kwizinto ezahlukeneyo zeplastiki ukuze siqwalasele ngokuxhomekeke ekusebenzeni kwenxalenye yokugqibela okanye imveliso.

Enye yezona ntlaka zixhaphakileyo ezisetyenziselwa ukwenza amalungu omatshini yinayiloni, eyaziwa ngokuba yipolyamide (PA). Xa i-polyamide ixutywe ne-molybdenum, inomgangatho ogudileyo ukuze kube lula ukuhamba. Nangona kunjalo, iigiya zenylon-on-nylon azikhuthazwa kuba, njengeeplastiki, zivame ukunamathela kunye. I-PA ine-high wear kunye nokumelana ne-abrasion, kunye neempawu ezintle zoomatshini kumaqondo aphezulu. Inayiloni yinto efanelekileyo yoshicilelo lwe-3D ngeplastiki, kodwa ifunxa amanzi ngokuhamba kwexesha.

I-Polyoxymethylene (i-POM) iphinda ikhetheke kakhulu kwiindawo zoomatshini. I-POM yintlaka ye-acetal esetyenziselwa ukwenza i-DuPont's Delrin, iplastiki yexabiso esetyenziswa kwiigiya, izikrufu, amavili nokunye. I-POM inamandla aphezulu okuguquguquka kunye nokuqina, ukuqina kunye nokuqina. Nangona kunjalo, i-POM yonakaliswa yi-alkali, iklorini kunye namanzi ashushu, kwaye kunzima ukunamathelana.

Ukuba iprojekthi yakho luhlobo oluthile lwesikhongozeli, i-polypropylene (PP) lolona khetho lungcono. I-Polypropylene isetyenziswa kwizikhongozeli zokugcina ukutya kuba iyakwazi ukumelana nobushushu, ayinakumelana neoli kunye nezinyibilikisi, kwaye ayikhuphi iikhemikhali, nto leyo eyenza kukhuseleke ukutyiwa. I-Polypropylene inomlinganiselo obalaseleyo wokuqina kunye namandla eempembelelo, okwenza kube lula ukwenza iilophu ezinokugotywa ngokuphindaphindiweyo ngaphandle kokwaphuka. Inokusetyenziswa kwakhona kwimibhobho kunye nemibhobho.

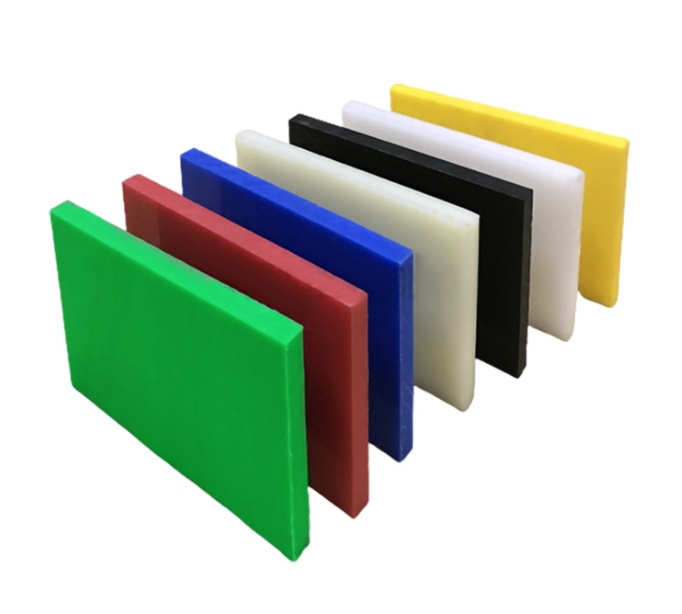

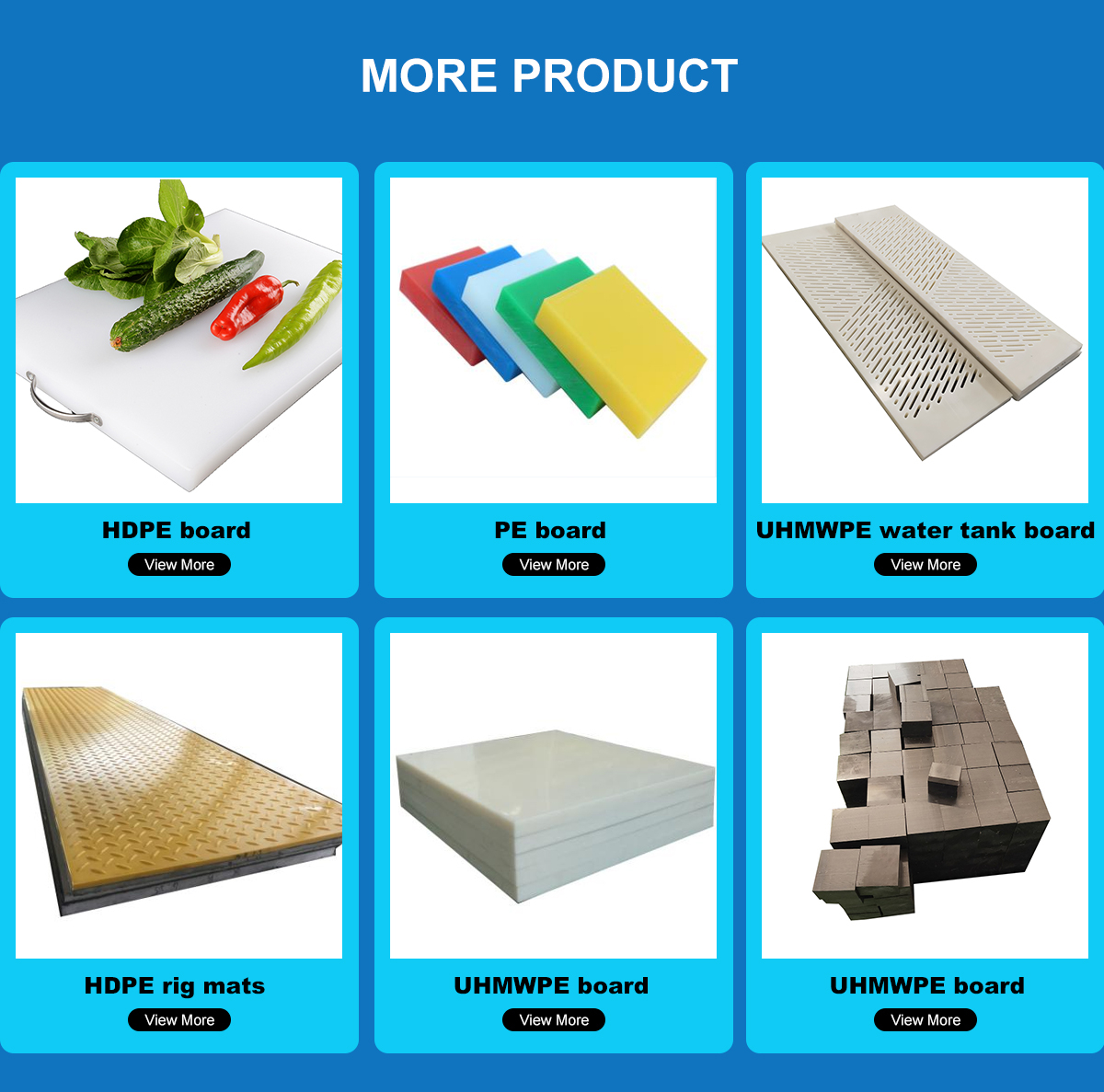

Enye inketho yi-polyethylene (PE). I-PE yeyona plastiki ixhaphakileyo emhlabeni ngamandla aphantsi, ubulukhuni kunye nokuqina. Idla ngokuba yiplastiki emhlophe enobisi esetyenziselwa ukwenza iibhotile zamayeza, ubisi kunye nezikhongozeli zokucoca. I-Polyethylene ixhathisa kakhulu kuluhlu olubanzi lweekhemikhali kodwa inendawo ephantsi yokunyibilika.

Izinto eziphathekayo ze-Acrylonitrile butadiene styrene (ABS) zilungele nayiphi na iprojekthi efuna ukuchasana kwempembelelo ephezulu kunye nokukrazula okuphezulu kunye nokuxhathisa ukuphuka. I-ABS ikhaphukhaphu kwaye inokomelezwa ngefiberglass. Ibiza kakhulu kune-styrene, kodwa ihlala ixesha elide ngenxa yobunzima kunye namandla. I-Fusion-molded ABS 3D imodeli yeprototyping ekhawulezayo.

Ngenxa yeempawu zayo, i-ABS lukhetho olulungileyo lwezinto ezinxitywayo. Kwi-Star Rapid, senze i-smartwatch case ye-E3design sisebenzisa inaliti emnyama epeyintwe ngaphambili ye-ABS/PC yeplastiki. Olu khetho lwezinto eziphathekayo lwenza ukuba isixhobo sonke sibe lula, ngelixa sikwabonelela ngetyala elinokumelana nokothuka ngamaxesha athile, njengaxa iwotshi ibetha indawo enzima. Impembelelo ephezulu yepolystyrene (HIPS) lukhetho olulungileyo ukuba ufuna izinto ezininzi kunye nefuthe elixhathisayo. Esi sixhobo sifanelekile ukwenza iimeko zesixhobo samandla ezomeleleyo kunye neemeko zesixhobo. Nangona i-HIPS ifikeleleka, ayithathwa njengenobuhlobo nokusingqongileyo.

Iiprojekthi ezininzi zifuna inaliti yokubumba i-resin enwebekayo njengerabha. I-Thermoplastic polyurethane (TPU) lukhetho olufanelekileyo kuba ineendlela ezininzi ezikhethekileyo ze-elasticity ephezulu, ukusebenza kobushushu obuphantsi kunye nokuqina. I-TPU ikwasetyenziswa kwizixhobo zamandla, iirola, ukugqunywa kwentambo, kunye nempahla yezemidlalo. Ngenxa yokumelana ne-solvent, i-TPU ine-abrasion ephezulu kunye namandla okucheba kwaye ingasetyenziswa kwiindawo ezininzi zemizi-mveliso. Nangona kunjalo, iyaziwa ngokufunxa ukufuma kwi-atmosfera, okwenza kube nzima ukusetyenzwa ngexesha lemveliso. Xa kusenziwa isitofu, kukho irabha ye-thermoplastic (TPR), engabizi kakhulu kwaye kulula ukuyiphatha, njengokwenza iintambo zerabha ezifunxa ukothuka.

Ukuba inxalenye yakho idinga iilensi ezicacileyo okanye iifestile, i-acrylic (PMMA) iyona nto ingcono. Ngenxa yokuqina kwayo kunye nokuxhathisa i-abrasion, le nto isetyenziselwa ukwenza iifestile ezinqabileyo ezifana ne-plexiglass. I-PMMA iphinda ipolishi kakuhle, inamandla okuqina, kwaye inexabiso elisebenzayo kwimveliso yevolumu ephezulu. Nangona kunjalo, ayikho impembelelo okanye i-chemical resistant njenge-polycarbonate (PC).

Ukuba iprojekthi yakho ifuna imathiriyeli eyomeleleyo, iPC yomelele kune-PMMA kwaye ineempawu ezibalaseleyo zamehlo, iyenza ibe lukhetho olufanelekileyo kwiilensi kunye neefestile zembumbulu. I-PC inokugoba kwaye yenziwe kwiqondo lokushisa ngaphandle kokuphuka. Oku kuluncedo kwiprototyping kuba ayifuni zixhobo zokubumba ezibizayo ukwenza. I-PC ibiza kakhulu kune-acrylic, kwaye ukuvezwa ixesha elide kumanzi ashushu kunokukhupha iikhemikhali ezinobungozi, ngoko ke ayihambelani nemigangatho yokhuseleko lokutya. Ngenxa yempembelelo yayo kunye nokunganyangeki, iPC ifanelekile kwiintlobo ezahlukeneyo zezicelo. Kwi-Star Rapid, sisebenzisa le mathiriyeli ukwenza izindlu zeetheminali ze-Muller Commercial Solutions eziphathwayo. Inxalenye yayiyi-CNC yomatshini ukusuka kwibhloko eqinileyo yePC; ekubeni kwakufuneka icace ngokupheleleyo, yayigatywa ngesandla yaze yagudiswa ngomphunga.

Lo ngumbono nje omfutshane wezinye zeplastiki ezisetyenziswa kakhulu kwimveliso. Uninzi lwezi lunokuguqulwa ngeentsinga zeglasi ezahlukeneyo, izizinzi ze-UV, izithambiso okanye ezinye iireyini ukufezekisa iinkcukacha ezithile.

UGordon Stiles ngumseki kunye nomongameli weStar Rapid, iprototyping ekhawulezayo, izixhobo ezikhawulezayo kunye nenkampani eyenza umthamo ophantsi. Ngokusekwe kwimvelaphi yakhe yobunjineli, uStiles waseka iStar Rapid ngo-2005 kwaye phantsi kobunkokeli bakhe inkampani ikhule yaba ngabasebenzi abangama-250. I-Star Rapid isebenzisa iqela lamazwe ngamazwe leenjineli kunye neengcali ezidibanisa itekhnoloji ye-cutting-edge efana noshicilelo lwe-3D kunye ne-CNC ye-multi-axis machining kunye neendlela zokuvelisa zendabuko kunye nemigangatho ephezulu. Ngaphambi kokujoyina i-Star Rapid, iZitayile bezizezakwaye zisebenza STYLES RPD, eyona nkampani inkulu yase-UK yokuchwetheza ekhawulezayo kunye nezixhobo zokusebenza, eyathengiswa kwi-ARRK yaseYurophu ngo-2000.

Ixesha lokuposa: Apr-19-2023